How to improve competitiveness of linear strip ceiling machine?

2025-02-13 17:00

Linear strip ceiling machine is a crucial equipment in the suspended ceiling production line. It provides essential materials for the construction and decoration industry by processing metal coils into linear strip ceilings of different specifications and shapes.

With the changes in market demand and the intensification of competition, manufacturers of linear ceiling panel machines must continue to improve technology and enhance the market competitiveness of equipment. This article will explore in depth how to improve the market competitiveness of linear strip ceiling equipment, including the technical upgrade of equipment, the grasp of market demand, and how to meet customer needs through innovation.

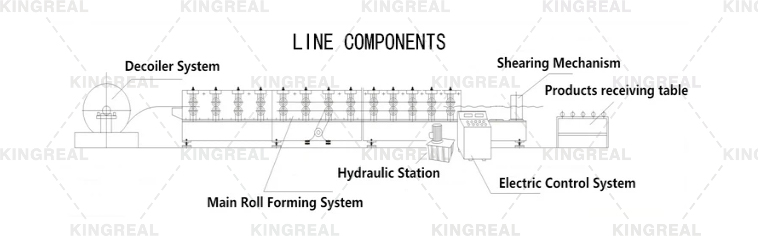

Introduction of linear strip ceiling production line

Linear strip ceiling machine is a device that uses a series of mechanical processing processes to produce linear strip ceilings through metal raw materials. Specifically, the workflow of linear ceiling panel machine includes unwinding, leveling, forming, cutting and other steps. After completing these processes, the metal material is processed into linear strip ceilings of different types and specifications, which are widely used in ceiling decoration in shopping malls, office buildings, stations and other places.

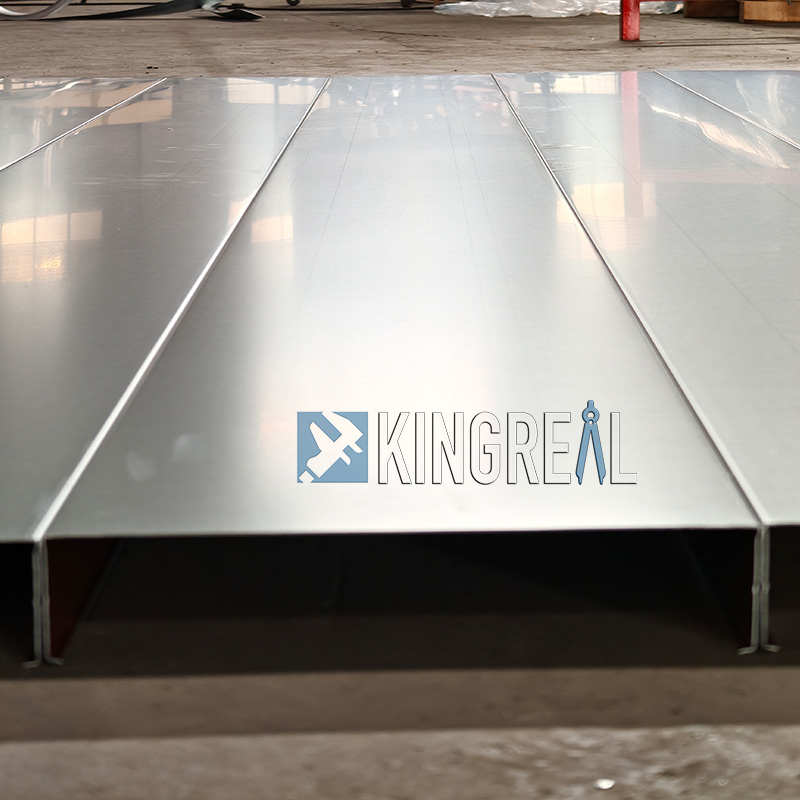

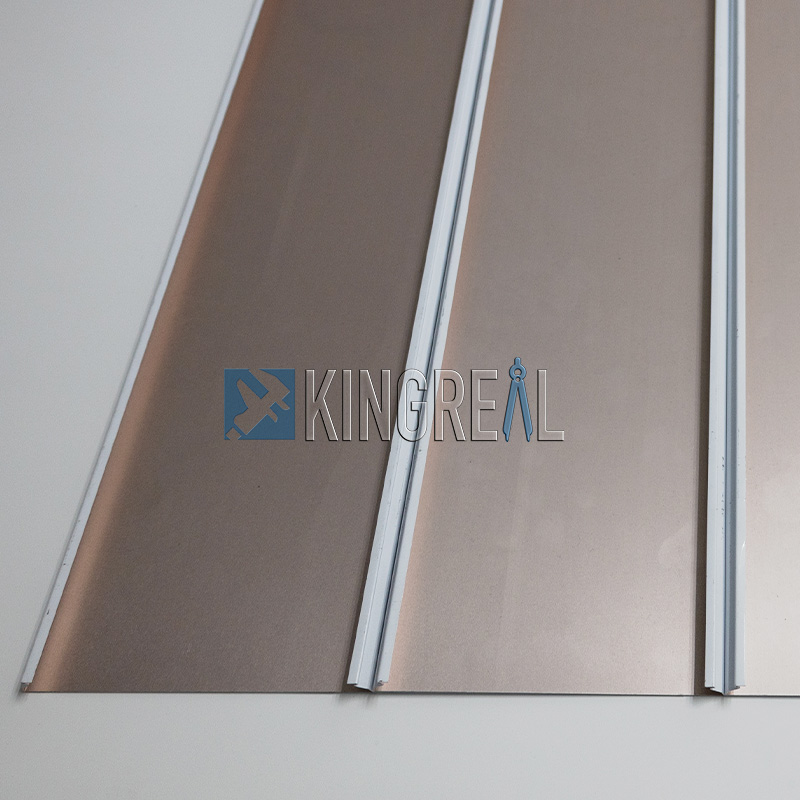

Common types of linear strip ceilings include C-type, G-type, V-type, U-type, H-type, etc. Different types of strip ceilings can be produced by special linear strip ceiling machines.

Market analysis: common machines in the market and customer needs

At present, the common linear strip ceiling production lines on the market often have problems such as low production efficiency and complex operation. Most machines can only produce strip ceilings of a single specification and lack flexibility, which limits the product diversification and market adaptability of manufacturers.

Through market research, KINGREAL CEILING MACHINERY found that customers' demand for linear strip ceiling equipment is concentrated in the following aspects:

1

High efficiency

Customers hope to produce a large number of high-quality strip ceilings in a shorter time to improve production efficiency.

2

Precision

The size, shape, surface quality and other requirements of strip ceilings are getting higher and higher, and customers need higher precision equipment to ensure product consistency.

3

Low energy consumption

With the rise in energy prices, customers are more inclined to choose equipment with lower energy consumption to reduce production costs.

4

Intelligence

Customers hope to reduce labor costs and improve the stability and reliability of the production process through automated and intelligent equipment.

KINGREAL CEILING MACHINERY technological innovation and upgrading

In order to cope with changes in market demand, KINGREAL CEILING MACHINERY has upgraded the linear strip ceiling machine with a new technology and developed several new linear strip ceiling equipment, aiming to improve production efficiency, product quality and meet the diverse needs of customers.

1. Different linear ceiling panel machine models

Due to the diversity of market demand, customers need to choose suitable linear strip ceiling machines according to different ceiling types. In order to meet this demand, KINGREAL CEILING MACHINERY has developed a variety of linear strip ceiling machines, such as C-type linear ceiling panel machine, V-type linear ceiling panel machine, G-type linear ceiling panel machine, etc. These different models are optimized for strip ceilings of different specifications and shapes, which can meet the personalized needs of different customers.

2. linear strip ceiling equipment with punching station

KINGREAL CEILING MACHINERY launched a linear strip ceiling equipment with punching station. By integrating the punching machine in the linear strip ceiling machine, customers can directly complete the punching process during the production process, reducing additional production links and improving production efficiency.

3. Adjustable width and narrow linear strip ceiling machine

For some customers who need to produce ceilings of different sizes, traditional linear strip ceiling machines can usually only produce products of fixed specifications, which limits the diversification and flexibility of the production line. In order to meet this demand, KINGREAL CEILING MACHINERY launched an adjustable width and narrow linear strip ceiling machine, which allows users to adjust the width of the strip ceiling as needed, so as to realize the production of ceilings of different sizes on one production line.

Get the latest price? We'll respond as soon as possible(within 12 hours)