How to improve operating safety of open cell ceiling machine?

2025-02-15 17:00

Importance of safe machine operation

In the modern construction and decoration industry, open cell ceiling machines are widely used in the production process of metal ceilings. The efficiency and precision of this equipment make it play a vital role in the production line.

However, with the improvement of automation and mechanization, how to ensure the safe operation of open cell ceiling production line has become an issue that must be paid attention to in enterprise management and production.

Machine use specifications

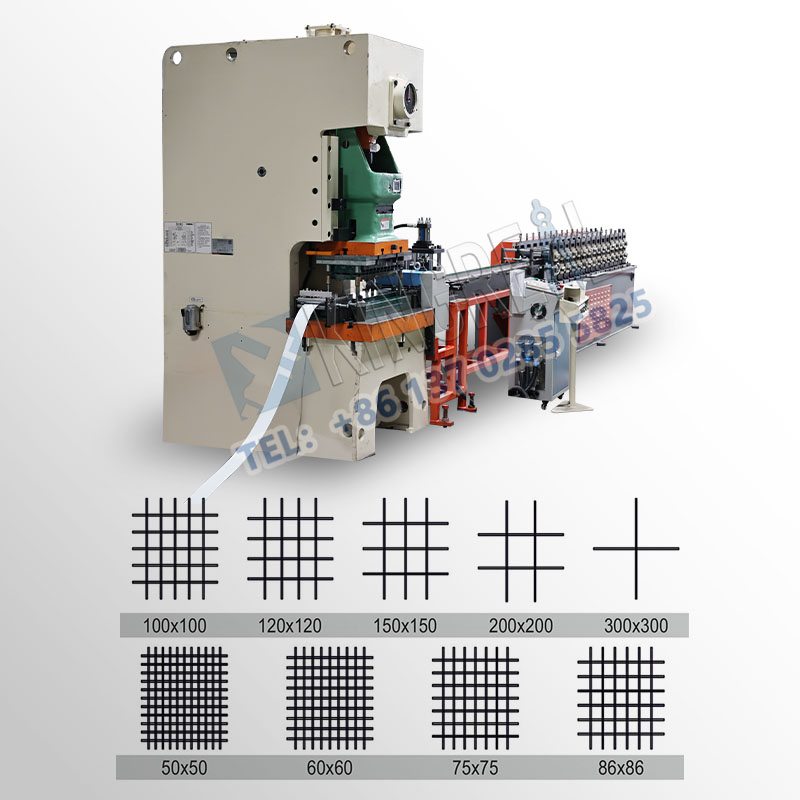

The workflow of the open cell ceiling making machine usually includes uncoiling, leveling, punching, forming, cutting and other links. Each link involves different mechanical parts and operating procedures. Therefore, in the operation of each step, the machine use specifications must be strictly followed to ensure safe operation.

Uncoiling

- Operation requirements: Uncoiling is the first step of the open cell ceiling machine, requiring the operator to ensure that the coil is placed correctly and that the coil tension of the equipment is within a safe range. Excessive tension can easily cause the coil to deviate, and even cause accidents such as material breakage and tearing. Before uncoiling, the coil and the machine must be inspected to ensure that there is no damage or abnormality.

- Safety measures: During the unwinding process, the machine should be kept running stably to avoid sudden start or stop. The operator must wear protective gloves and protective glasses, and ensure that the emergency stop device of the equipment is effective. Avoid starting the machine before the coil is fully unrolled to prevent material jamming and equipment damage.

Leveling

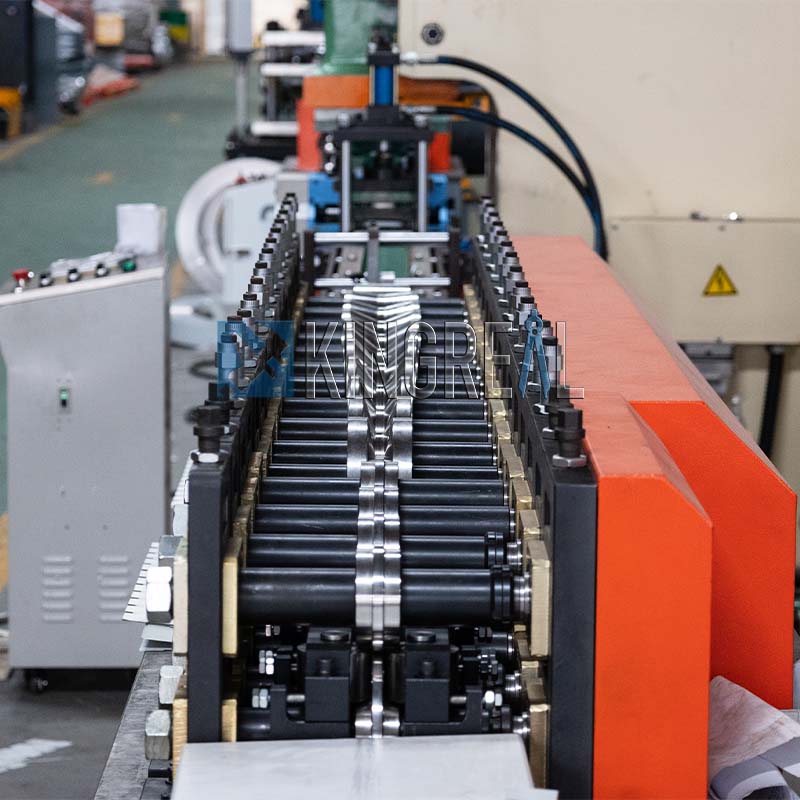

- Operation requirements:Leveling is a process of flattening the coil to ensure that the metal sheet has no obvious warping or waves. The operator needs to check the adjustment of the leveler to ensure that the roller is in good contact with the metal sheet to avoid defects caused by uneven extrusion during the leveling process.

- Safety measures: During the leveling process, the operator should always pay attention to the feeding of the metal sheet to avoid foreign objects or irregular sheets from entering the open cell ceiling roll forming machine. In order to avoid the hands or other parts of the body being pinched by the rollers, the operator must stay away from the running part of the machine and ensure that no one is standing in the leveling area.

Punching

- Operation requirements: The punching process is to punch holes in the metal sheet through mechanical impact force. This process has high requirements for the impact force, accuracy and operation speed of the equipment. The operator should ensure that the metal punching machine's die is installed correctly and check whether the metal punching machine's tool is sharp to avoid inaccurate hole position or jamming caused by tool wear.

- Safety measures: When punching, the operator needs to ensure that the workpiece is fixed to avoid injury caused by workpiece displacement. During this process, any hand contact should be avoided, and the operator should wear necessary safety accessories such as protective gloves and goggles to ensure safety.

Forming

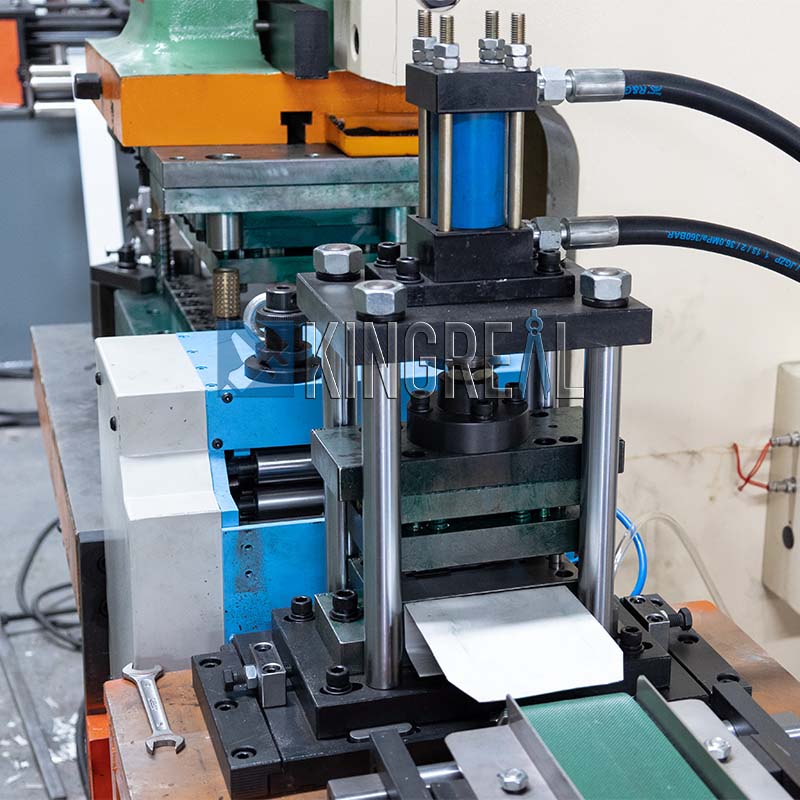

- Operation requirements: Forming is the process of shaping the metal plate according to the predetermined die. This link requires high force control and precision of the equipment. The machine's pressure system must be in normal working condition, and the operator should regularly check the pressure adjustment device to ensure that there is no leakage and looseness.

- Safety measures: The operator should stay away from moving parts when operating the forming link and avoid contact with the equipment. The emergency stop button of the equipment should be available at any time to ensure that the power can be cut off in time when an emergency occurs to prevent further danger.

Cutting

- Operation requirements: Cutting is the process of cutting the formed metal plate to the required length. At this time, the equipment's knives must be sharp and the shearing force must be appropriate to avoid jamming. The operator should ensure that the knives are installed correctly and check the operating status of the shearing part regularly.

- Safety measures: During the shearing process, the operator must maintain a safe distance and never put his hands close to the shearing area. For the shearing operation of large plates, it is recommended that more than two people work together to avoid contact when the equipment is not completely stopped.

Safety measures that must be followed

To ensure the safe operation of the open cell ceiling machine, in addition to the standardized operating procedures, a series of safety measures must be strictly implemented to ensure the safety of the operating environment. The following are the main safety measures that must be followed during operation:

Workers wear safety accessories

All operators must wear appropriate safety accessories such as protective gloves, safety shoes, goggles, earplugs, etc. before entering the production site to prevent injuries caused by noise and material splashing generated by the open cell ceiling roll forming machine.

Especially in the punching and shearing process, the staff should wear thick protective gloves to prevent metal fragments from injuring people.

On-site supervision and management

In each operation link, experienced management personnel must be arranged on site to supervise to ensure that each operation step complies with safety regulations. Managers should monitor the operating status of the equipment in real time to promptly detect and deal with potential safety hazards.

Regular inspection and maintenance of equipment

The open cell ceiling machine should be regularly maintained and serviced, especially key components such as motors, transmission systems, molds, etc. Regularly check and replace worn parts to avoid operational safety problems caused by equipment failure.

Get the latest price? We'll respond as soon as possible(within 12 hours)