What's the purpose of ceiling t bar machine?

2025-03-21 17:00

Definition of ceiling t bar machine

Ceiling t bar machine is a kind of equipment specially used to produce ceiling t grids of various sizes and types. Its workflow includes unwinding, forming, punching, cutting and other steps, and finally forms ceiling t bar suitable for different decoration needs. Common types of ceiling t grid include flat t bar ceilings, flat black line t bar ceilings, FUT ceiling t bar and groove ceiling t grid.

Ceiling t grids are an important part of the ceiling system, responsible for supporting and fixing the ceiling materials to make them flat and stable. With the development of the construction and interior decoration industries, the application of ceiling t grid machines has become more and more extensive and has become an indispensable equipment in modern buildings.

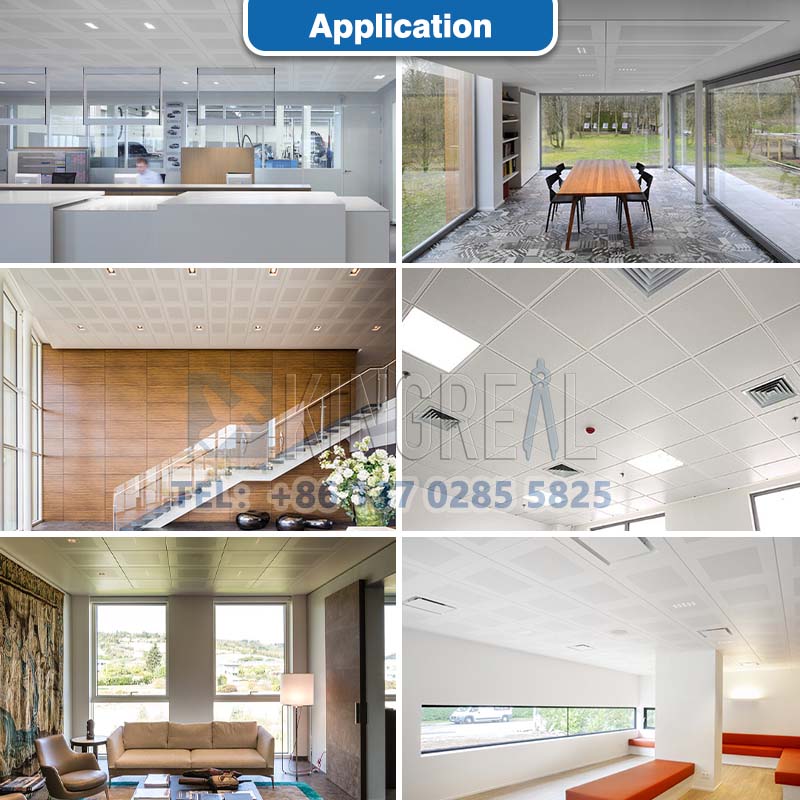

Application field of ceiling t bars

Ceiling t grids are mainly used for ceilings and can be used with LAY IN ceiling systems. The main t bar and the cross t bar form the frame of the ceiling frame to ensure the flatness and beauty of the ceiling. Specific applications include:

1. Commercial space: In commercial spaces such as shopping malls, offices, and hotels, they are used in ceiling systems to provide good acoustic and lighting effects.

2. Residential: In home decoration, they can be used for ceilings in living rooms, bedrooms, kitchens and other areas to improve the indoor aesthetics and sense of space.

3. Public facilities: Such as schools, hospitals, conference centers and other places, ceiling t bar systems provide good ventilation and sound insulation for these spaces.

4. Industrial buildings: In industrial places such as factories and warehouses, the use of ceiling t grid systems can effectively support lighting and ventilation equipment.

The supporting function of the ceiling t grid not only ensures the stability of the ceiling, but also can hide facilities such as pipes and cables, and improve the neatness of the space.

Working principle of ceiling t grid machine

The working principle of t bar ceiling roll forming machine mainly includes the following key components:

1. Hydraulic Decoiler: The decoiler is used to unfold the coil to ensure the flatness of the material, which is convenient for subsequent forming and processing.

2. Main Roll Forming Machine: The roll forming machine is the core part of the ceiling t grid machine, which processes the unfolded material into the required ceiling t grid through a series of forming rollers. By adjusting the configuration of the rollers, ceiling t grids of different sizes can be produced.

3. Punching and Shearing Station: During the forming process, the punching and shearing system is responsible for punching and shearing the ceiling t grids to ensure the accuracy of the product and meet the design requirements.

4. Product Table: The product table is used to receive the finished ceiling t bar for subsequent packaging and transportation.

The entire workflow achieves efficient automated production, improving production efficiency and product quality.

Advantages of ceiling t grid machine

T bar ceiling roll forming machines have shown many advantages in modern architecture and interior decoration, including:

Producing ceiling t grids of different sizes

The design of the ceiling t grid machine allows the production of ceiling t grids of different sizes by simply adjusting the rollers. This flexibility enables manufacturers to quickly adjust the production line according to market demand, improving production efficiency and adaptability.

Smart Control Panel

KINGREAL CEILING MACHINERY's ceiling t grid machine is equipped with a smart control panel, which is simple and intuitive to operate. Users can set the cutting length, set the output, and adjust the production speed. This intelligent design not only improves the convenience of operation, but also reduces the possibility of human error and ensures the stability of production.

Protective shield

Safety is always an important consideration in the design of production equipment. KINGREAL CEILING MACHINERY has equipped the t bar ceiling roll forming machine with a protective shield to reduce potential safety hazards and ensure the safety of workers during operation. This design effectively prevents accidental injuries and enhances the safety of the ceiling t grid machine.

Independent archway

KINGREAL CEILING MACHINERY's roll forming machine adopts an independent archway design to ensure the smooth operation of the ceiling t grid machine. This design not only improves the durability of the t bar ceiling roll forming machine, but also reduces the probability of failure, thereby reducing maintenance costs.

Market demand and future development of ceiling t grid machines

With the vigorous development of the construction industry, the market demand for ceiling t grids is also growing. Especially in the context of accelerated urbanization, the decoration demand for commercial spaces and residences is increasing, and the application prospects of t bar ceiling roll forming machines are broad.

1. Growing market demand

According to market research, the global construction industry will continue to grow in the next few years, especially in emerging markets such as the Asia-Pacific region and Latin America. As people's requirements for the quality of interior decoration increase, the demand for ceiling t bar as an important part of the ceiling system will continue to rise.

2. Technological innovation and upgrading

Faced with market competition, t bar ceiling roll forming machine manufacturers need to continuously innovate technology and upgrade equipment to improve production efficiency and product quality. KINGREAL CEILING MACHINERY will continue to invest in research and development to promote the progress of t bar ceiling roll forming machines in automation and intelligence to meet the growing needs of customers.

3. Environmental protection and sustainable development

With the increase in environmental awareness, the construction industry is also moving towards a green and sustainable direction. Ceiling t grid machine manufacturers need to pay attention to the selection of raw materials and environmental protection measures in the production process to reduce the impact on the environment. The use of recyclable materials and energy-saving production processes will become a trend of future development.

Get the latest price? We'll respond as soon as possible(within 12 hours)