Hot Products

About Us

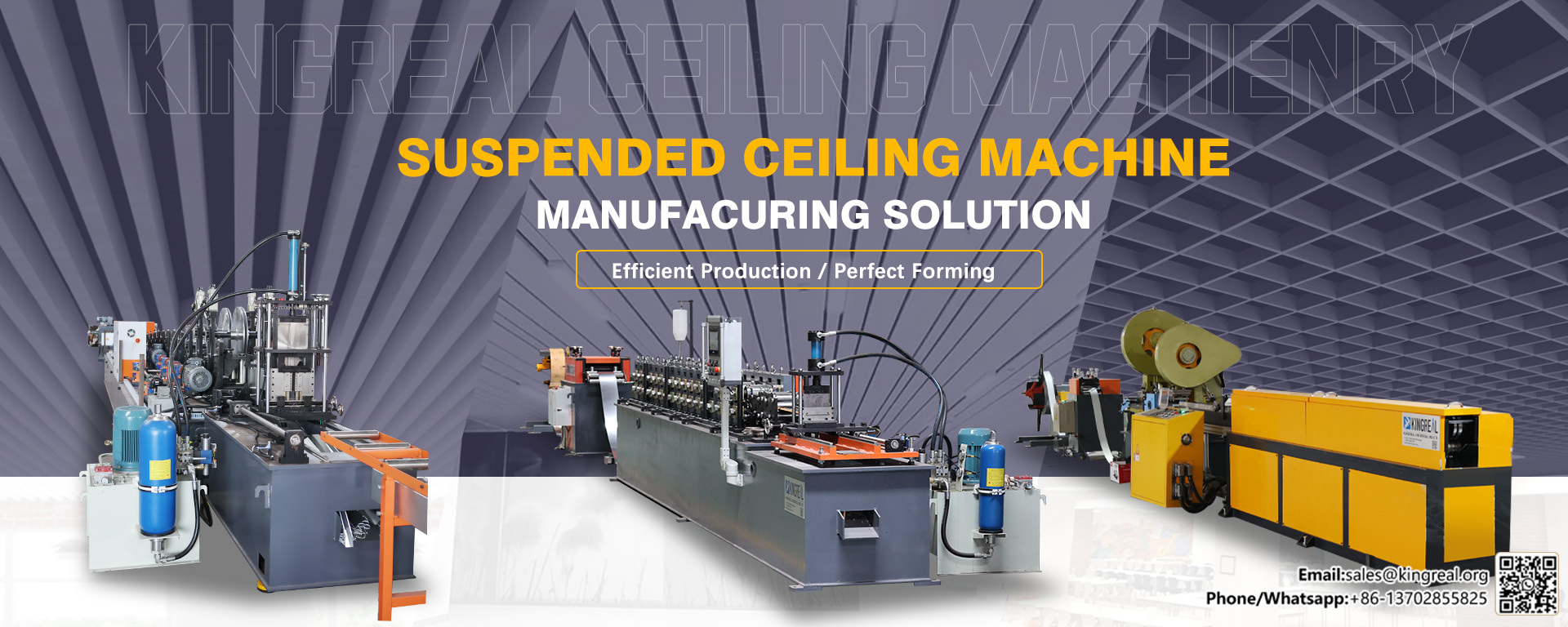

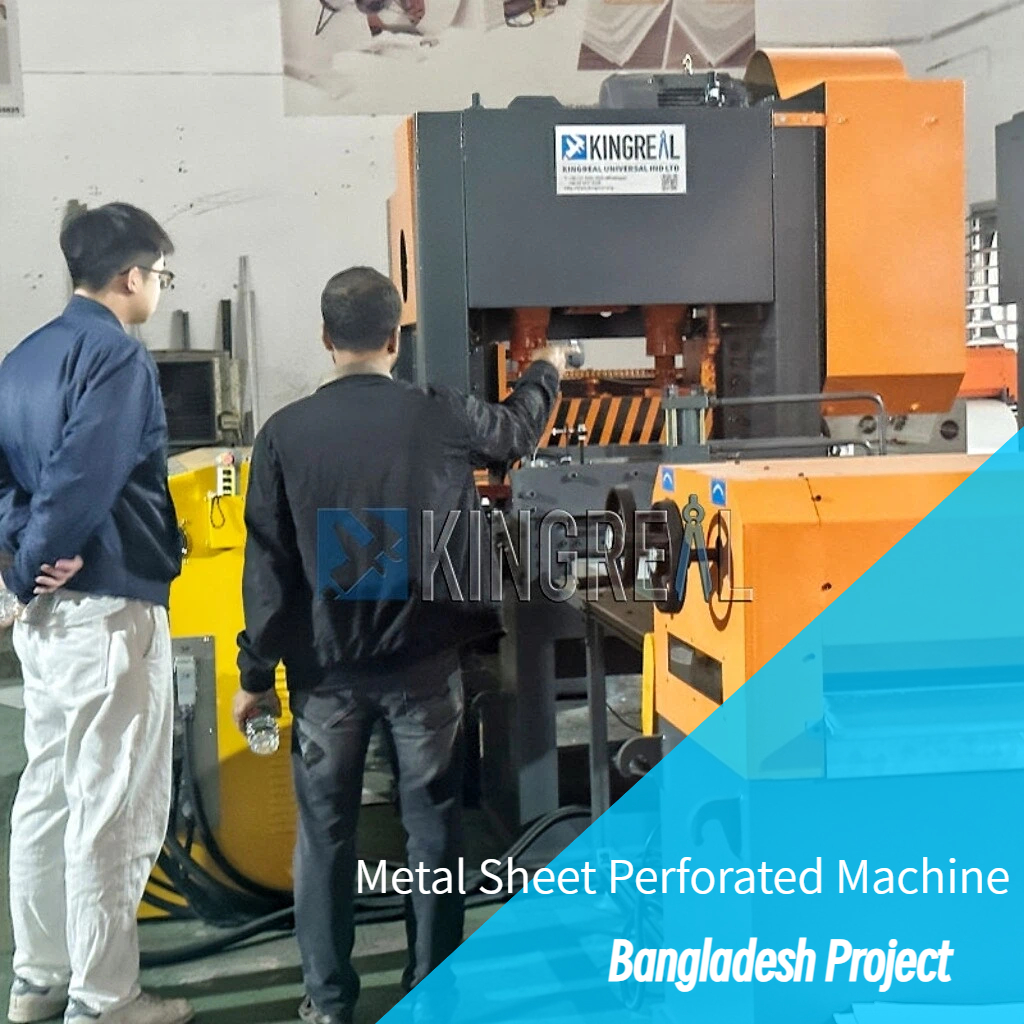

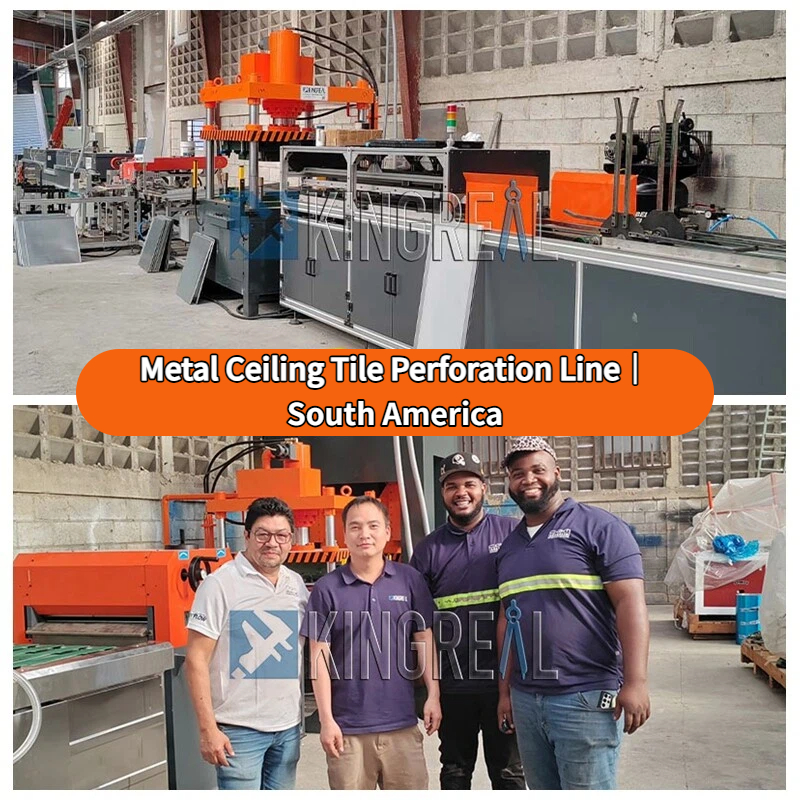

"KINGREAL CEILING MACHINERY develops and manufactures machines for a variety of industries, including metalworking, construction, automotive, and marine. KINGREAL CEILING MACHINERY offers the best solutions for semi-automatic to fully automated production lines. Located in Foshan, Guangdong, KINGREAL CEILING MACHINERY employs a team of experienced engineers and skilled production and testing personnel. Using the latest design software, KINGREAL CEILING MACHINERY precision and durable equipment are capable of producing a wide range of high-precision finished products. All engineering processes are performed in a fully equipped machine shop, staffed by experienced machine operators and technicians operating the most advanced CNC technology. KINGREAL CEILING MACHINERY also has a sales center in Guangzhou, Guangdong, with a responsive and professional service team. KINGREAL CEILING MACHINERY has successfully completed over 500 projects in over 50 countries over the past 28 years, including the United States, Canada, Mexico, Brazil, Russia, and the Middle East. KINGREAL CEILING MACHINERY provides personalized support and advice based on customer drawings and actual production requirements, and is committed to finding customized machine solutions that meet their needs.”

MoreNews

-

02/12-2026

Baffle Ceiling Machine Shipped to DominicanRecently, after being carefully manufactured and rigorously trialed by the KINGREAL CEILING MACHINERY technical team, the baffle ceiling machine has completed full process testing, professional rust prevention packaging, and standardized assembly operations. It has officially departed from the KINGREAL CEILING MACHINERY factory and sailed all the way to the designated port, successfully boarding the ship and heading to the customer's factory in Dominican.

-

02/01-2026

New Project: Metal Stamping Making MachineKINGREAL CEILING MACHINERY has always focused on market dynamics and actively responded to the latest project needs of its customers, continuously improving the competitiveness of machines through technological research and development and product innovation. Recently, two metal stamping making machines designed by KINGREAL CEILING MACHINERY for a customer in Turkmenistan have been manufactured and are currently undergoing commissioning. This metal stamping press will provide an efficient and precise solution for the customer's facade project in Turkmenistan.

-

01/30-2026

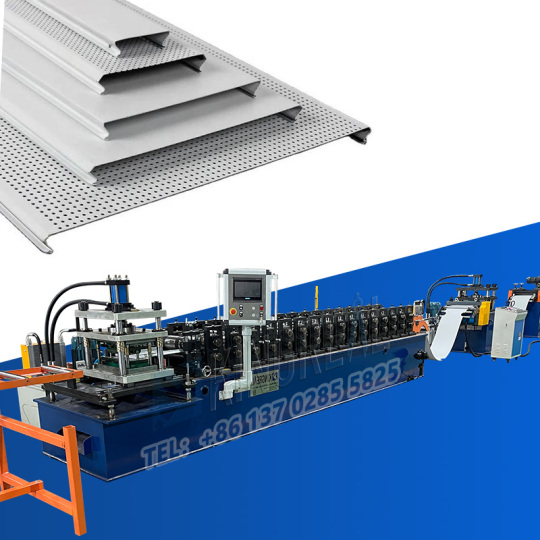

Metal Perforated Making Machine for Baguette PanMetal perforated making machines are typically used for multiple process steps on metal materials such as galvanized steel sheets with a thickness of 0.4-2.0 mm, including uncoiling, leveling, punching, cutting, and recoiling. Through these processes, the metal perforated machine can punch various holes on the material surface, thus producing high-quality perforated materials. Today, metal perforated making machines are widely used in many industries, one of which is the manufacturing of baguette pans. This article will explore the importance of metal perforated machines in baguette pan production and their working principles.