What are the advantages of a sheet metal leveling machine?

2025-03-03 17:00

Brief introduction of plate straightening machine

1.1 Definition of metal sheet straightening machine

Plate straightening machines are special equipment used to level metal materials. Through a series of mechanical operations, sheet metal leveling machines can significantly improve the flatness of materials and lay the foundation for subsequent processing steps. Metal sheet straightening machines play a vital role in many industrial fields such as metal processing, construction, aviation, and automobiles.

1.2 Function of plate straightening machine

The main function of a metal sheet straightening machine is to correct uneven metal materials through mechanical force to make their surfaces flat. This process usually involves placing the material into a plate straightening machine and leveling the material through specific pressure and movement patterns. The specific functions of a sheet metal leveling machine include:

1. Remove ripples and bends: Eliminate ripples and bends caused by processing or storage by applying pressure.

2. Improve surface quality: The surface of the leveled material is smoother, which is helpful for subsequent processing, such as welding, painting, etc.

3. Enhance material strength: During the leveling process, the internal stress of the material will be released, thereby improving its strength and stability.

1.3 Importance to the industrial industry

The importance of plate straightening machines in the industrial industry cannot be underestimated. With the rapid development of the manufacturing industry, production processes are becoming increasingly complex, and the requirements for materials are becoming higher and higher. As an important equipment for improving the flatness of materials, plate straightening machines can effectively improve production efficiency and product quality. Almost every metal processing plant, automobile manufacturing plant, construction engineering company, etc., cannot do without the support of metal sheet straightening machines.

Basic structure and workflow of metal sheet straightening machines

2.1 Basic structure of plate straightening machine

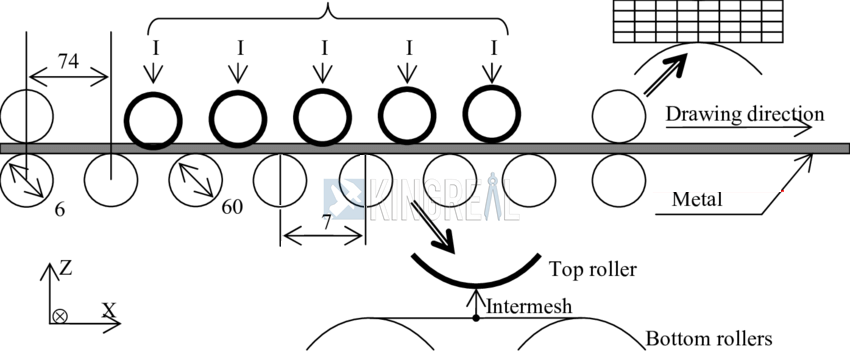

The basic structure of a plate straightening machine usually includes the following main components:

1. Feeding device: used to feed the metal material to be leveled into the metal sheet straightening machine.

2. Leveling roller: It is the core component of the plate straightening machine, usually composed of multiple groups of rollers. By adjusting the spacing and pressure of the rollers, the leveling process of the material is achieved.

3. Drive system: Provides power for the metal sheet straightening machine, usually including motors, reducers, etc.

4. Control system: Used to monitor and adjust various parameters in the leveling process, including pressure, speed and feed rate, etc.

5. Discharging device: Send the leveled material out of the leveler.

2.2 Workflow of plate straightening machine

The workflow of the plate straightening machine is generally divided into the following steps:

1. Feeding: The metal material to be leveled is fed into the sheet metal leveling machine through the feeding device.

2. Leveling: The leveling roller applies a specific pressure to the material, and the material is stretched and compressed under the action of the roller, thereby achieving the leveling effect.

3. Detection: During the leveling process, the control system monitors the flatness of the material and adjusts it as needed.

4. Discharging: The leveled material is sent out through the discharging device and is ready for subsequent processing.

The working principle of the plate straightening machine is relatively simple, but its design and manufacturing requirements are quite high. The metal sheet straightening machine can only operate efficiently under the premise of ensuring accuracy and stability.

Advantages of the sheet metal leveling machine

The metal sheet straightening machine has multiple advantages in industrial applications. The following is a detailed analysis of its main advantages:

Improve efficiency

A significant advantage of the plate straightening machine is that it can greatly improve production efficiency. Traditional leveling methods often require manual work, which is time-consuming and labor-intensive, and the results are unstable. The automated operation of the metal sheet straightening machine can significantly shorten the time required for leveling.

- Save manpower: The automated design of the sheet metal leveling machine means less reliance on manual work. Operators only need to start, adjust and monitor the equipment, which greatly reduces the workload.

- Speed up production: The efficient workflow of the plate straightening machine can process a large amount of material in a short time, thereby improving the efficiency of the entire production line. Compared with manual leveling, the production cycle can be shortened by 30% to 50% after using the metal sheet straightening machine.

Improve flatness

The sheet metal leveling machine can achieve higher flatness through professional mechanical design. Its advantages are reflected in the following aspects:

- Precisely control pressure: The plate straightening machine can accurately control the applied pressure according to the characteristics of different materials to achieve the best leveling effect. Traditional manual leveling methods are difficult to achieve this.

- Consistency: The processing process of the metal sheet straightening machine is highly consistent, and different batches of materials can maintain the same flatness. This is crucial for subsequent processing steps (such as welding, painting, etc.), because any slight difference may affect the quality of the final product.

Strong adaptability

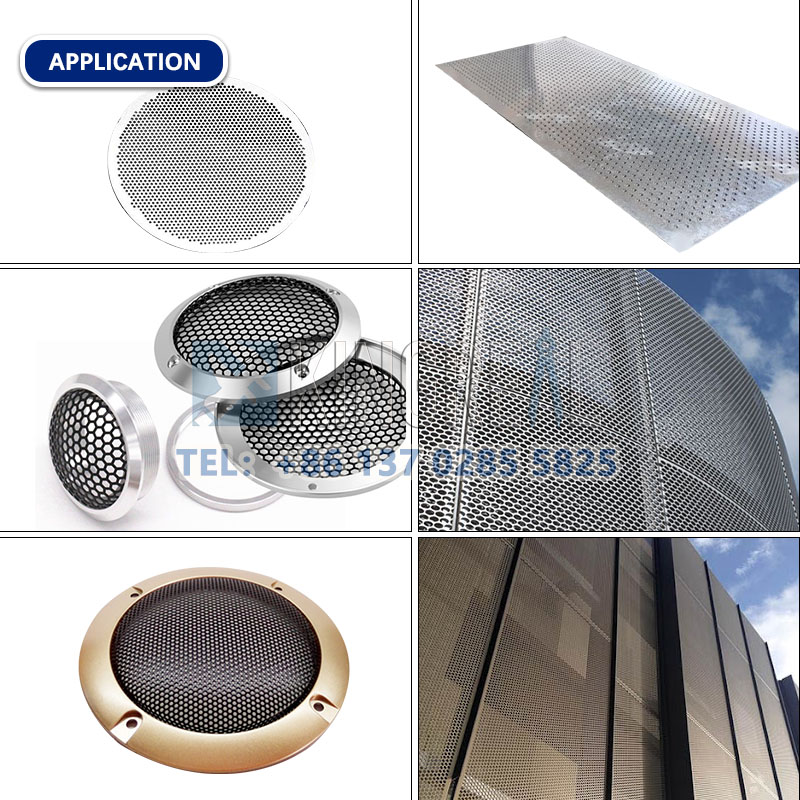

The adaptability of the sheet metal leveling machine is also a major advantage. It can handle a variety of metal materials, including:

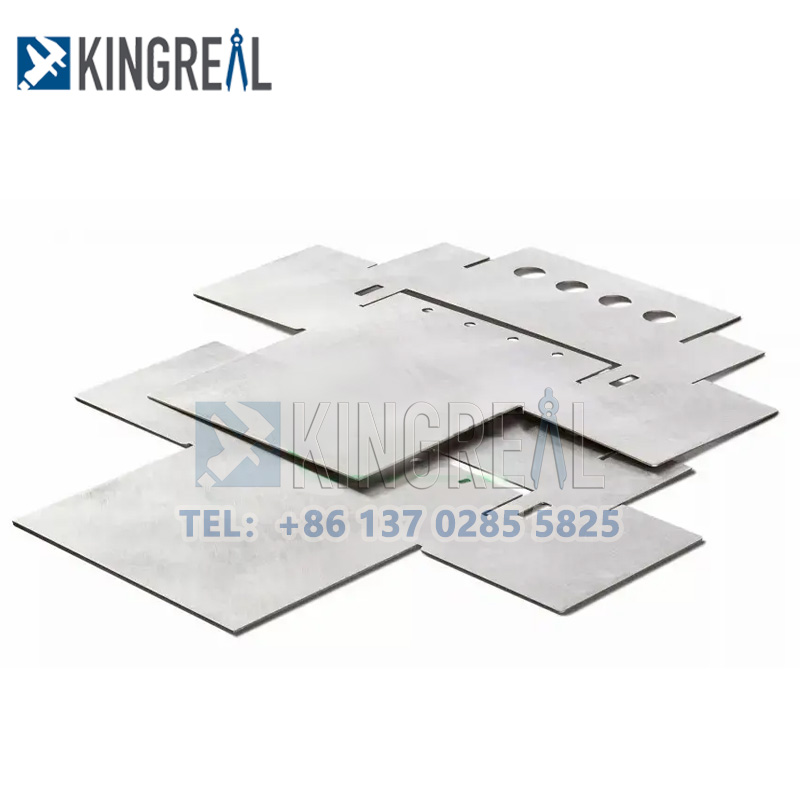

- Plates: Whether it is thin or thick plates, the plate straightening machine can efficiently level them to meet the production needs of materials of different thicknesses.

- Perforated mesh: The metal sheet straightening machine can handle mesh materials with punched holes to ensure that they maintain good shape and performance after leveling.

- Hexagonal bars and metal parts: The plate straightening machine can also handle metal parts of various shapes, such as hexagonal bars, square bars, etc., with strong adaptability.

- Metal bars: For metal bars of various widths and lengths, the metal sheet straightening machine can also effectively level them and improve their performance.

This adaptability allows the plate straightening machine to play an important role in many industries. From construction to automobiles, from aviation to precision manufacturing, the application range of the sheet metal leveling machine is extremely wide.

Cost savings

The use of sheet metal leveling machines can not only improve efficiency and quality, but also significantly save production costs in the long run.

- Reduce scrap rate: Since the metal sheet straightening machine can provide consistent leveling results, the scrap rate caused by uneven materials is reduced, thereby reducing production costs.

- Extend the service life of materials: The performance of the leveled material is more stable, which can extend its service life in subsequent processing and reduce losses caused by material quality problems.

- Reduce energy consumption: Modern plate straightening machines usually use efficient motors and optimized workflows, with relatively low energy consumption, which helps companies reduce production costs.

Get the latest price? We'll respond as soon as possible(within 12 hours)