What metal ceiling perforation line can produce?

2025-03-05 17:00

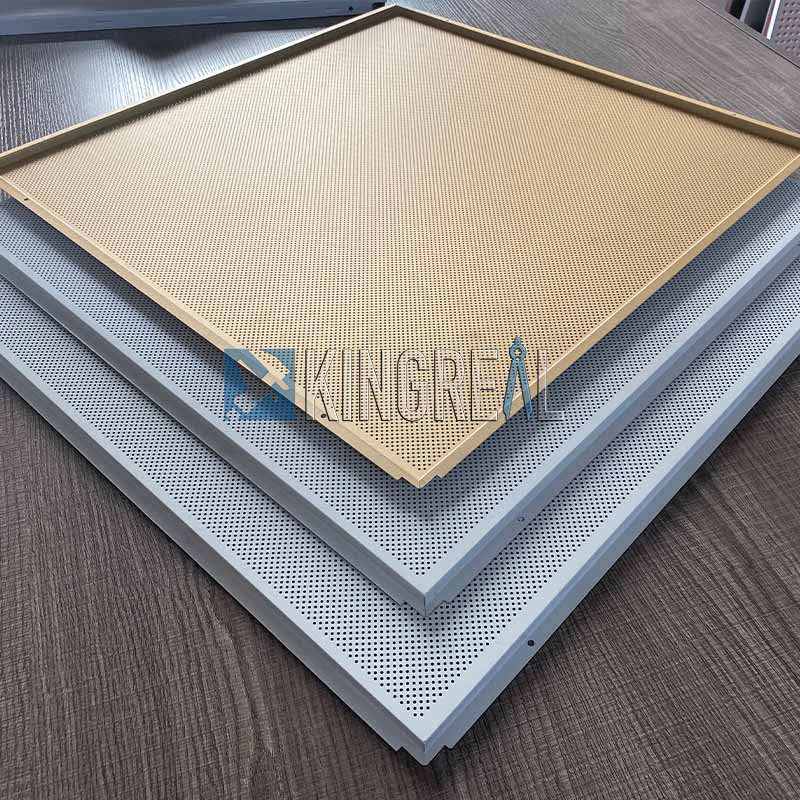

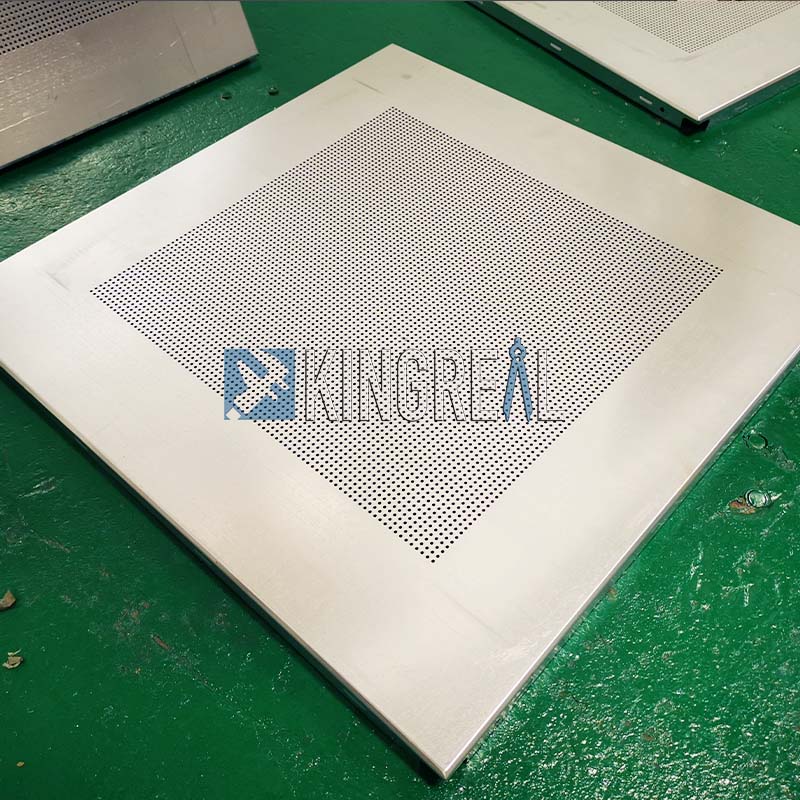

Metal ceiling perforation line is a special equipment for the production of perforated ceilings, through a series of workflows such as unwinding, leveling, punching, etc., can produce different sizes and types of perforated ceilings. These ceilings are used in a wide variety of locations and are produced in specifications including the common 30x30 cm, 60x60 cm and 60x120 cm clip-in, lay-in and tegular types. These perforated ceilings not only have a beautiful appearance, but also effectively improve the acoustics and air permeability of the interior, providing a variety of options for modern architecture.

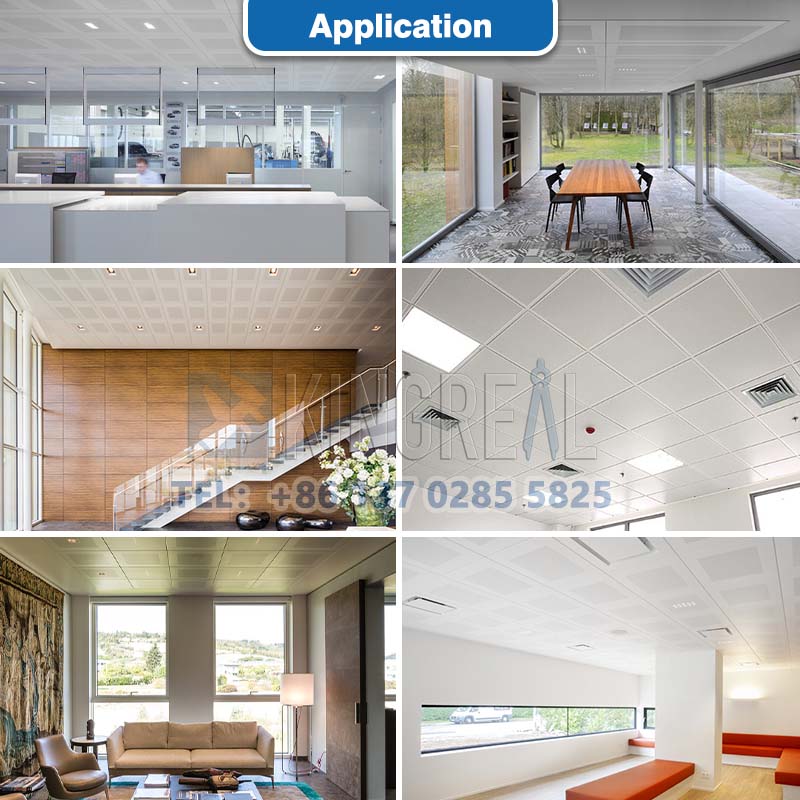

Application field of perforated ceiling

Perforated ceilings are ubiquitous in our daily lives, and their applications are wide ranging, covering commercial buildings, industrial buildings, home decoration and special places.

1. Commercial buildings

In commercial buildings, such as shopping malls, office buildings and hotels, perforated ceilings produced by the ceiling punching line are widely used. These ceilings are not only beautiful, but also provide good acoustic performance, reducing noise interference and creating a comfortable working and shopping environment. The ceilings of shopping malls are often perforated to better hide pipes and wires while enhancing the overall visual effect.

2. Industrial buildings

Industrial buildings usually need to withstand greater noise and pollution, and perforated ceilings perform well in this regard. They can effectively absorb noise and improve the comfort of the working environment. In addition, the durability and ease of cleaning of perforated ceilings make them ideal for industrial plants and warehouses.

3. Home improvement

In home decoration, the application of perforated ceilings is also becoming more and more common. The interior decoration requirements of modern homes are constantly increasing, and perforated ceilings are favored for their diverse design and color options. Whether in the living room, bedroom or kitchen, perforated ceilings add a sense of style and beauty to a house.

4. Special places

Perforated ceilings also play an important role in special places such as hospitals and schools. In hospitals, a good acoustic environment can help patients recover faster; In school, a quiet learning environment is crucial to students' learning effectiveness. In addition, the fire and moisture resistance characteristics of the perforated ceiling make it more suitable for these occasions.

Different market demands for metal ceiling tile perforation line

With the continuous development of the construction industry, the market demand for perforated metal ceiling tile machines is increasing. Especially in Saudi Arabia, India, the United States, Mexico and other countries and regions, different market needs and industry characteristics of the perforated ceiling requirements are different.

Regional differences

The difference in demand for metal ceiling tile perforation lines in different regions is mainly reflected in the thickness of raw materials, the width of the coil and the punching design. For example, some regions may focus more on energy conservation and environmental protection, while others may focus more on production efficiency and cost control. KINGREAL CEILING MACHINERY is able to provide solutions according to the specific needs of customers and market characteristics.

Industry demand

There are also significant differences in the demand for perforated metal ceiling tile machines in different industries. For example, commercial buildings may be more oriented towards aesthetic and acoustic performance, while industrial buildings are more concerned with durability and clean maintenance. In home decoration, consumers may be concerned about the diversity of design and the choice of color. In order to meet these different needs, the design and production of perforated ceilings need to be adjusted accordingly.

Customized production

In order to adapt to the needs of different customers and markets, manufacturers of metal ceiling tile perforation lines need to have flexible production capabilities. KINGREAL CEILING MACHINERY can customize different perforated metal ceiling tile machines according to customers' specific parameter requirements (such as raw material thickness, coil width, aperture design, etc.) to ensure that the ceiling produced meets the diverse needs of the market.

Advantages of metal ceiling tile perforation line

As a professional machine manufacturing supplier, KINGREAL CEILING MACHINERY has accumulated more than twenty years of experience in the production and sale of perforated metal ceiling tile machines. The metal ceiling tile perforation lines of KINGREAL CEILING MACHINERY are not only sold to many countries and regions such as Turkey, Brazil, UAE, India, Greece, Saudi Arabia and North Korea, but also enjoy a good reputation in the market.

The following are the significant advantages of the perforated metal ceiling tile machine of KINGREAL CEILING MACHINERY:

Efficient automation

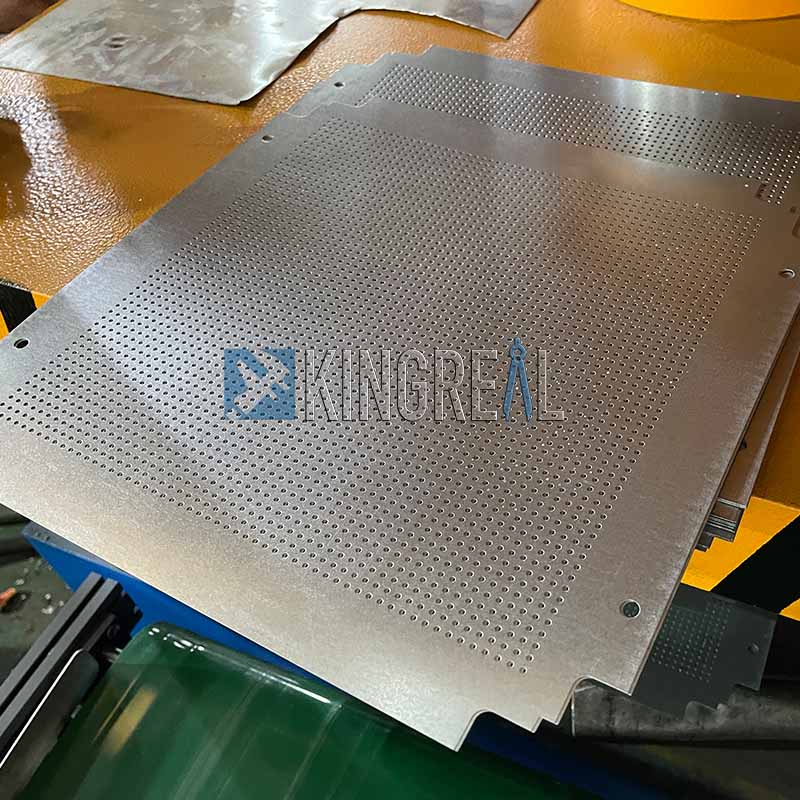

KINGREAL CEILING MACHINERY's metal ceiling tile perforation line integrates multiple automation components such as decoiler, leveling machine and punching machine. By setting the parameters, the perforated metal ceiling tile machine can operate fully automatically, with little need for human intervention. This highly efficient automated production process not only improves production efficiency, but also significantly saves time and labor costs, enabling enterprises to maintain an advantage in the fierce market competition.

Customized manufacturing solutions

KINGREAL CEILING MACHINERY understands that each customer's needs are unique, so KINGREAL CEILING MACHINERY offers customized metal ceiling tile perforation line manufacturing solutions. Based on the detailed parameter information provided by the customer, including the aperture, the thickness of the raw material, etc., the engineers of KINGREAL CEILING MACHINERY are able to design a dedicated perforated metal ceiling tile machine to meet the specific needs of the customer. This flexible customization capability enables KINGREAL CEILING MACHINERY to provide a more personalized and efficient service to its customers.

Quality control and precision

In the production of perforated ceilings, the precision of perforation is crucial. KINGREAL CEILING MACHINERY's metal ceiling tile perforation line uses advanced punching technology to ensure that each hole is the same diameter and position, and that the aperture is smooth and free of barbs. This high-precision punching can effectively improve the quality of the finished product, ensuring stability and durability in a variety of application scenarios.

Use with metal ceiling production line

To meet the diverse needs of our customers, KINGREAL CEILING MACHINERY also offers complete metal ceiling production line solutions. KINGREAL CEILING MACHINERY's perforated metal ceiling tile machine can be seamlessly connected to the metal ceiling production line for a more efficient production process. This combination of use not only improves the production efficiency, but also optimizes the utilization of resources, so that the overall production cost can be reduced

Get the latest price? We'll respond as soon as possible(within 12 hours)